Scooter–Wheelchair Mobility Link

A hybrid mobility system engineered for accessibility, affordability, and real-world use.

Designed and built by Michael Beshay and Peter Kalds

The Problem

Mobility scooters and wheelchairs are essential for millions, but they come with significant barriers. Traditional wheelchairs require constant manual effort. Powered mobility scooters are expensive, bulky, and inflexible.

Existing solutions often cost thousands of dollars and lock users into a single mode of movement. What if there was a better way?

The goal was simple: create a system that combines the manual flexibility of a wheelchair with the convenience of powered mobility (without breaking the bank).

The Idea

The solution emerged from a simple insight: don't reinvent the wheelchair or the scooter. Connect them.

Manual wheelchair first

Functional standalone, lightweight, easy to maneuver indoors

Scooter attachment second

Clamp-based connection for outdoor powered mobility

No permanent modifications

Easy attach and detach, flexibility over complexity

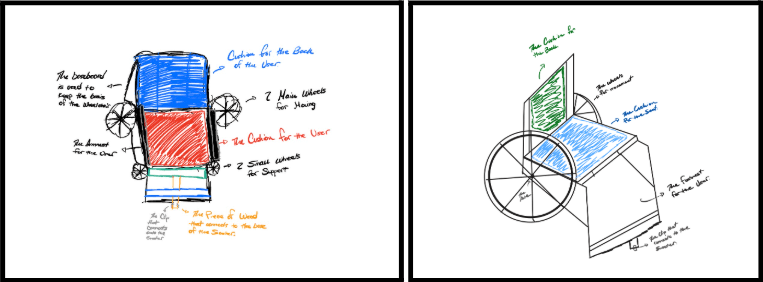

Design & Engineering

Every decision was intentional. Every material was chosen for a reason.

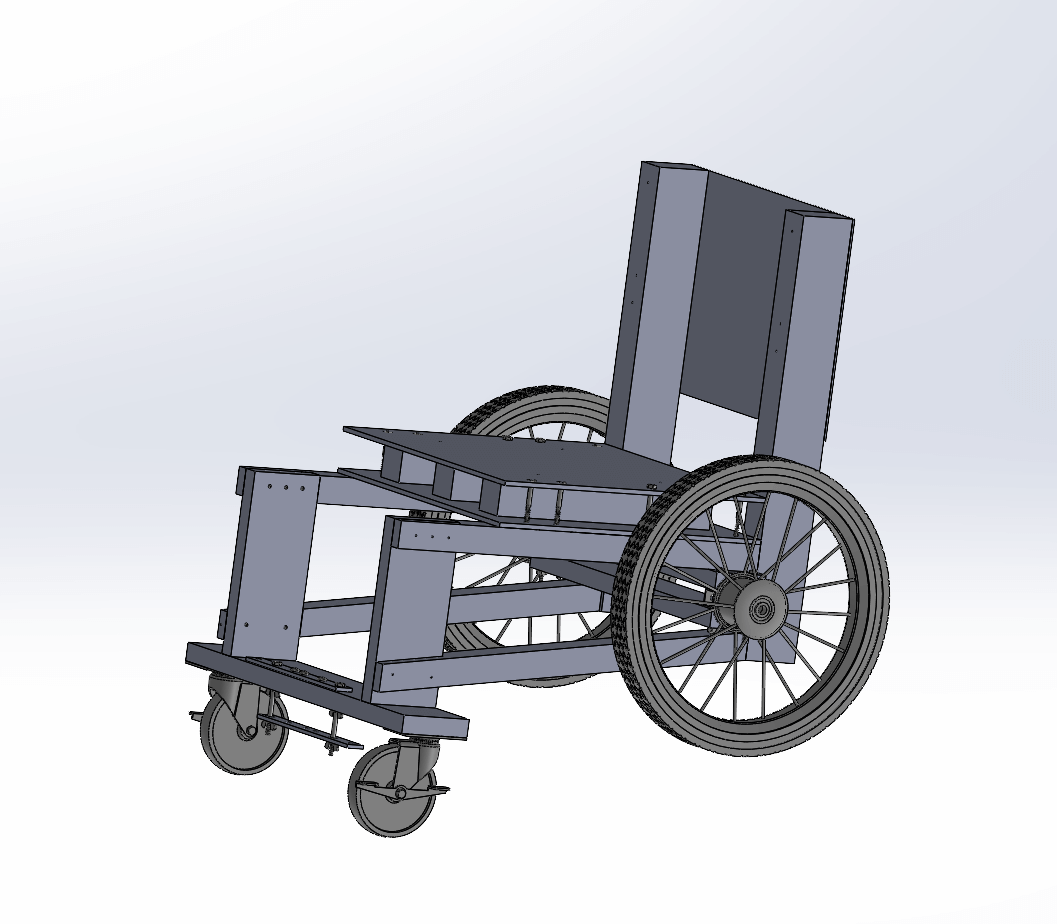

Material Choice: Wood

Wood was the foundation. Strong, affordable, and easy to work with. The structural rails and posts provide rigidity while keeping weight manageable.

Unlike metal fabrication, wood allowed for rapid iteration and adjustment without specialized equipment.

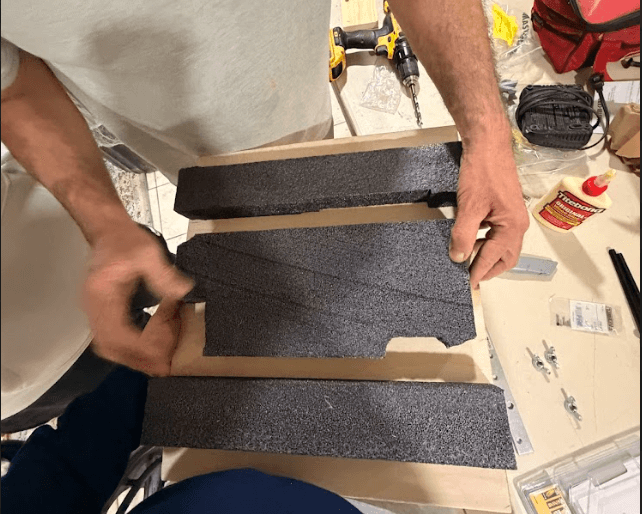

Load Distribution

The frame was engineered to support 250+ pounds while maintaining structural integrity. Strategic placement of cross-bracing and support struts ensures stability under load.

Simplicity over overengineering—every component serves a purpose.

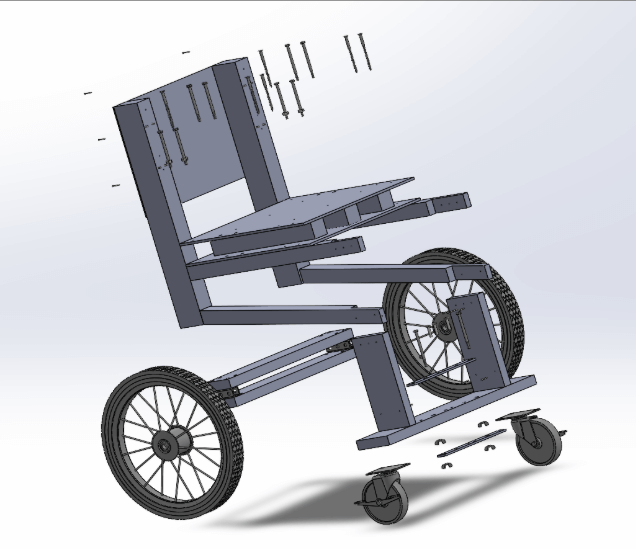

Clamp Connection

The front attachment uses a clamp-based system to connect with the mobility scooter. No drilling, no permanent modification—just secure, reliable connection.

This preserves the independence of both devices while enabling hybrid functionality.

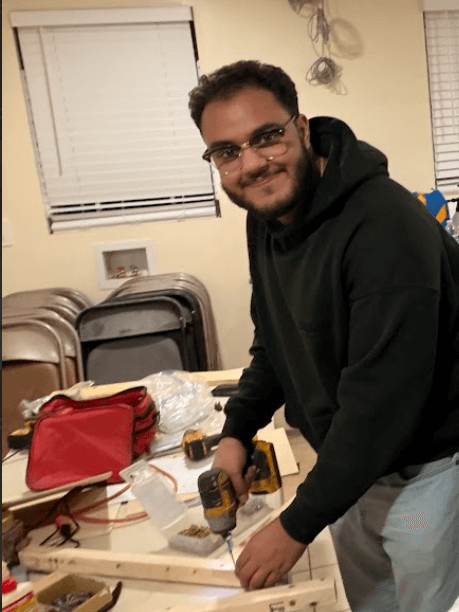

The Build

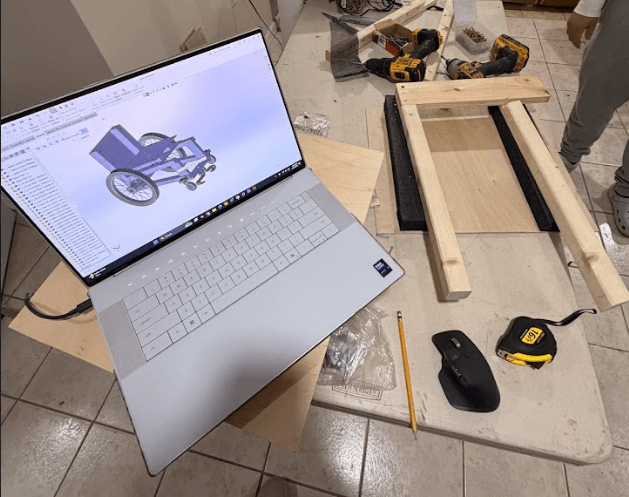

Engineering isn't just computer models. It's sawdust, iteration,

and problem-solving in real time.

Precision cutting. Measure twice, cut once

Frame assembly and structural testing

Hardware installation and adjustment

Engineering through collaboration

Where ideas become reality

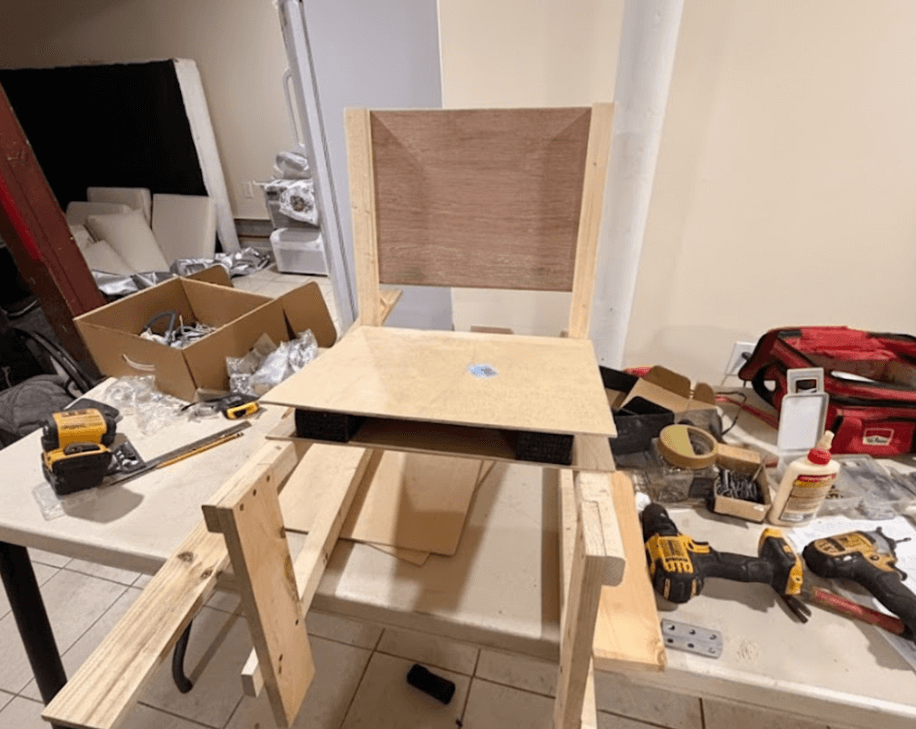

Taking shape. Final assembly stages

"Dimensions change. Plans adapt. The hands-on work reveals what the computer model can't predict. That's where real engineering happens."

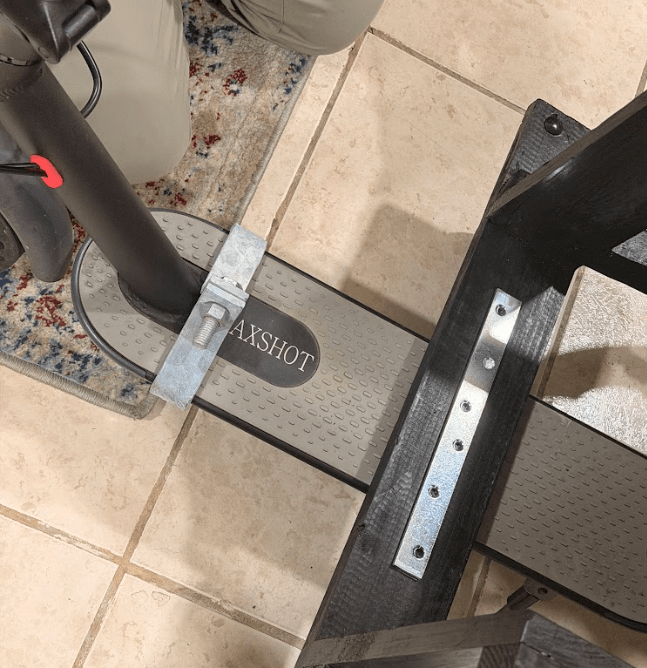

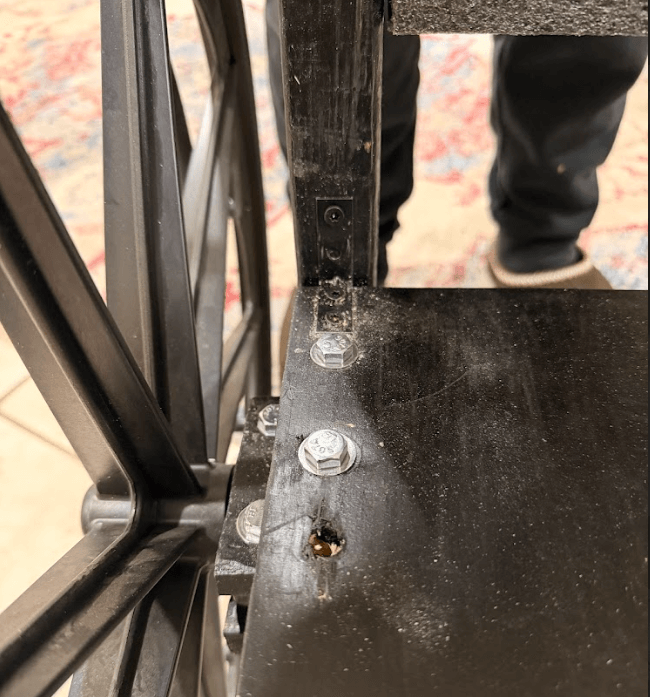

The Setback

High-speed testing revealed a critical weakness.

After detaching from the scooter at speed, the foot rest area failed under stress. The connection point couldn't handle the dynamic load.

This is normal. Expected, even. Real engineering isn't about perfection on the first try, it's about finding failures and fixing them.

The Fix

Resolution through reinforcement.

Before: Structural weakness at connection point

After: Multiple 90° brackets for load distribution

Added multiple 90-degree brackets to redistribute stress across a wider area. Improved load distribution restored structural integrity and eliminated the failure point.

Stability restored. System functional.

Testing & Result

The proof is in the performance.

Manual mode: Functional. Lightweight, easy to maneuver, supports full user weight.

Scooter mode: Functional. Secure attachment, stable connection, powered mobility achieved.

Hybrid system: Successful.

Future Improvements

Engineering never stops. There's always a next iteration.

Second Clamp for Stability

Additional rear connection point to improve attachment rigidity

Improved Wheel Alignment

Fine-tune caster geometry for smoother rolling and turning

Arm Rest Integration

Adjustable arm rests for enhanced comfort and support

Ride Smoothness Refinements

Suspension or cushioning to reduce vibration during powered mode

The Takeaway

Engineering is problem-solving. Not in theory, in practice.

This project reflects real-world constraints: limited budgets, material limitations, and the need for practical functionality over aesthetic perfection.

Built by students. Driven by purpose. Designed to work.

— Michael Beshay and Peter Kalds